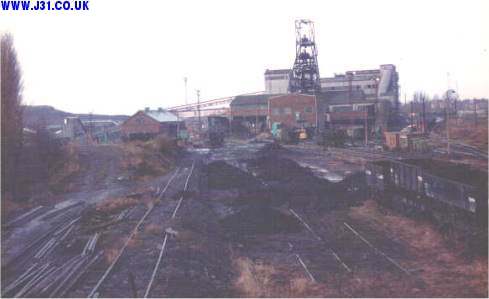

History of Kiveton Coliery

(written circa 1967, author unknown)

Kiveton Park Coal CO. LTD. as formed in March 1864. The Company consisted of 14 men with an estimated capital of œ200,000. Two of them MESSRS. DAWSON AND CARRINGTON, had [rows of] terraced houses in the district named after them. Most of the shareholders had interests in other collieries in Stafordshire, where mining began many years before it did in Yorkshire. At that time Kiveton Park was a rural village with not more than a dozen farm houses. It should be appreciated that the village of Wales, half a mile away, is much older having a Norman Arch in the church, and a Blacksmiths Forge no longer in use, which dates back to Cromwell. Thorpe Salvin, a village one and a half miles East has a chained Bible in the church, which was built about 1100 [the Church, not the Bible].

The reason why interest was focused on Kiveton Park was that the railway between Sheffield, Grimsby and Hull had been built in 1845 and collieries en route to Sheffield had an express route to the ports for shipping coal, and were recieving pit props and other materials in the wagons on their return to the colliery. Whilst it is digressing from the subject, there was a two hourly service from the fish docks to Sheffield each day. Sinking at Kiveton Park began on June 6th 1866. The Barnsley seam was reached on December 5th 1867 at a distance of 405 yards from the surface.

The reason the Barnsley seam was chosen was the fact that at that time every railway engine and every ship burnt coal as a motive power and the Bamsiey seam coal was an ideal fuel for the job. You will appreciate that no water, electricity, gas or telephone were in the district in 1864 to facilitate communications, Kiveton Park coal CO. had an office in Grimsby until November 1895 when a Telephone system was first introduced into this district. It was known as The National Telephone CO. The coal CO. negotiated with the Sheffield authority for 4" water mains to be laid in 1869. Previous to that water they used for the steam winding engines was obtained from reservoirs made at the colliery. Gas was initially obtained from Beighton Gas CO. in 1870 but the company made their own gas shortly after that until 1956 when it drew a supply from the grid. All electricity is now drawn from the grid. There was no piped sanitation in the district until 1908. Most of the 52 men who participated in the sinking of the shaft came From Staffordshire, many of them from Gresley. Later this shaft was sunk down to the Thorncliffe seam, 670 yards down. This coal was used for coking purposes and coke ovens were built at the colliery. Unfortunately the seam which was 3 feet 8 inches thick had a sins band of dirt in the middle which in those days was an uneconomical proposition and working in this seam was abandoned in 1896 i.e. 10 years after work commenced.

In 1896 another shaft was sunk adjacent to the Barnsley and connected to it. For ventilation purposes the shaft was sunk to the Silkston seam at a depth of 733 yards. Coal production from the High Hazel seam commenced from this shaft in 1900. The seam is 310 yards from the surface. High Hazel is a very good quality house coal, and the small coal was used for manufacturing purposes. Up to 1929 the method of working was hand got. Machine Mining including coal cutters and conveyors was introduced into the Barnsley seam in 1932. Hand got work being superceded entirely by machine in 1940. Power Loading, the American method, was introduced in 1944 using Joy Loader and Shuttle Car. Other methods of power loading were introduced in 1950 including Meco Moor cutter loders and A.B. Trepanners. A11 the output is now obtained from A.B. Trepanners.

Forty six houses were built in 1867 to provide immediate accomodation for the workmen and their families. A further 165 houses were built in 1928. The Coal Co. took a long lease over a further 100 houses in the district. The colliery offices were built in 1875 and as there was no school in the district the offices were used for this purpose. The school bell is still attached to the outside wall of the colliery offices. The council school in the village was built by the colliery in 1874, and the teachers were paid by them until the new Education Act in 1911 or 1912.

Village life remained practically unaltered until 1928 when, despite opposition from the local shop-keepers, a regular bus service to Sheffield 10 miles away and Worksop 7 miles away, was established. In that year a station was built on the railway line and people began to travel to town regularly rather than shop locally. Whilst there is light industry in proximity to the village, most young people have found work in the adjacent towns and travel daily. Kiveton Park has grown from an agricultural hamlet in 1864 with a dozen inhabitants to a prosperous industrial community of 6,000 people in 1966.

The colliery produces an average of between 5-600,000 tons of coal per annum. The amount has not varied greatly over the years but the number of men it now takes to produce that tonnage has halved. The greatest number of men employed by the colliery was 2,244 in April 1929, the saleable output per manshift for that year being 21 cwt. We now employ 1,054 men and the saleable output per manshift is over 40 cwts. They are employed as follows:- 416 coalface, 405 others underground, 233 surface. The mining industry was nationalised in 1947 and this brought many advantages to the men. Previous to this they had to work very hard for low wages. The system was that they received what they earned. There was much competition between collieries and combines of collieries to produce a cheap and plentiful supply of coal. The emphasis was on cheap coal and the men wore exploited and many safety measures were left undone. Whilst nationalisation has raised the price of coal many tines, there is no doubt that mechanisation has taken the hard work out of mining, and the capital available to such a large organisation has provided better working conditions and increased wages to all concerned. Under the new power loading structure all coalface workers will shortly receive a minimum of 82/6 per shift and one fifth of the amount daily as a bonus. One hundred and fifty new houses have been built in this district in recent years under the coal industry housing association, for the housing of transferred workers from districts in the north which have closed. Prior to the machine age 67% of the output was large lumps of coal, this being used for locos, shipping and household purposes. The small coal at that time was used for manufacturing purposes. As a result of total mechanisation the percentage of large coal is never more than 20%. A typical weeks saleable output is 10,000 tons, of which 7,500 is small coal destined for power stations, 500 tons of Barnsley cobble coal for locos and the remainder high hazel cobble coal for the domestic market, chiefly around Manchester.

With regard to transport, prior to nationalisation all the coal that left the colliery yard for private customers was transported by rail in a quiet efficient manner. A considerable amount of the slack coal for power stations is now transported by road, which most people consider is a retrograde step. Over œ1m. has been spent by the Board of Kiveton Park Colliery during the last two years on a major reconstruction scheme which included a new coal preparation plant and electric winding engines. 1967 is the centenary year for Barnsley seam. Unfortunately this seam will be worked out in three years time and it has not yet been decided whether future working at the colliery will consist of a more intensive opening out of other seams i.e. Melton Field, Silkstone. It will depend on the economic position at the time. The Barnsley seam has varied in thickness between 4'0" and 5'6" and been fortunate that the floor and roof have been generally good. The High Hazel seam has had a maximum thickness of 4' 0" but there is 18" of roof dirt above the seam known locally as Bannocking dirt, which is extremely friable and cannot be controlled at the present time. Three or four inches of coal roof is left in order to keep this dirt out of the coal which is extracted. Waleswood colliery was worked out in 1948 and most of the men came to Kiveton Park. Most of the pits on route to Sheffield have only a short life. They were opened early in the 19th century in order to provide fuel for Sheffield in the early part of the Industrial revolution. During the time the Thorncliffe seam was worked (1886-96) brick kilns were made and bricks were made and sold for industrial purposes.

Kiveton Park Colliery amalgamated with Sherwood Colliery in 1928 for Business reasons, including the quota system. Kiveton Park was taken over by the United Steel Co. in 1944 but in both instances the Kiveton Park directorate had over 50% of the shares of their own company. The pithead baths have accommodation for 1,750 men and were opened in August 1938 and the colliery canteen has just had a facelift [circa 1966]. Of the 1,054 men employed at present 500 live in Kiveton and the remainder in surrounding villages. Twenty men live at Sheffield and work at Kiveton Park.

Whilst the village is prosperous there is no culture. Most of what has occurred would have done so under the laws of evolution. The Chapel choirs, cinemas, local orchestras, and regular dance nights of the 1920's have disappeared. Holidays with pay were first introduced in 1936. Before then travel away from home was confined to day excursions. Now two or three week's holiday are a regular part of life.

Text kindly supplied by Pat Ward of Kiveton

Note - the pit was closed in the early 1990s during the 'dash for gas'.